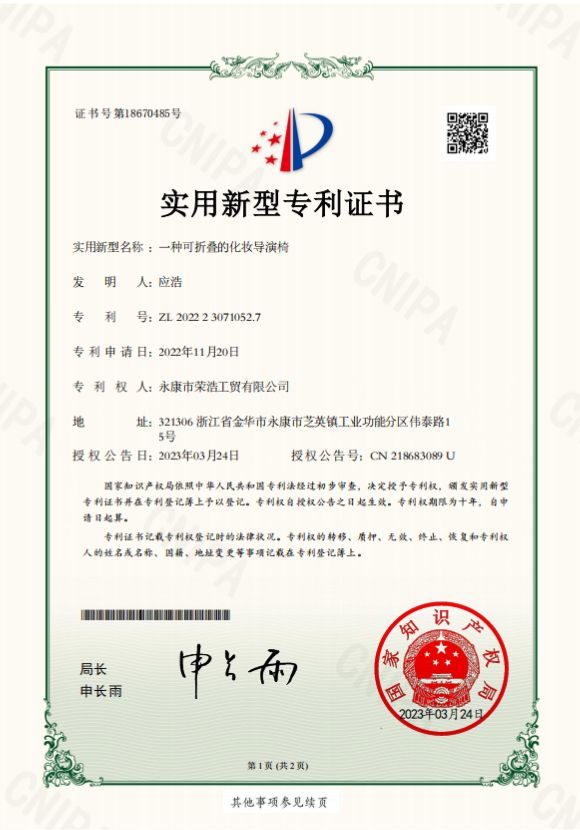

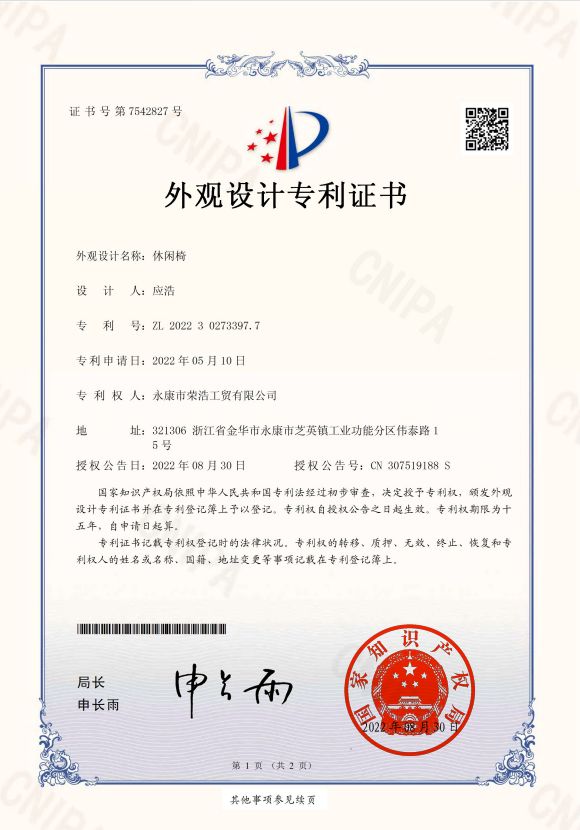

our factory

Factories we own

Unfolding the Art of Outdoor Living

In the heart of Yongkang, the capital of hardware manufacturing, Outave’s story began when we folded our first camping chair in 2011. Stemming from our founders’ vision to equip adventurers around the world with gear for simplified living, we committed to mastering the intricate art of folding form and function.

Today, over 300 dedicated minds construct leisure essentials within our 18,000 square meters of automated factories, from the initial bending of durable steel tubing to final quality assurance checkpoints. Our chairs, beds and tables reimagine camp comfort, while specialized products answer military personnel’s portable shelter needs even in harshest terrains.

When you invest in our catalog of products, you also invest in unlocking the full potential of life outdoors. Unfurl with us as we shape reliable gear for life’s journeys under nature’s roof one expert fold at a time. The passion of our people provides the foundation to support your next adventure.

Know outave-Made Facts

Numbers don’t lie – let our ture figures establish us as a competitive force in the camping gear industry.

Where Camp Gear Comes to Life

At our factory, we have an array of specialized production workshops dedicated to crafting our innovative camp gear. From cutting edge capabilities to unwavering attention to detail, our workshops enable us to take products from concept to creation entirely in-house.

Metalworking Workshop

Powder Coating Workshop

Fabric Processing Workshop

Assembly Workshop

Packaging Workshop

Warehouse

The Best-Engineered Gear, Built For You

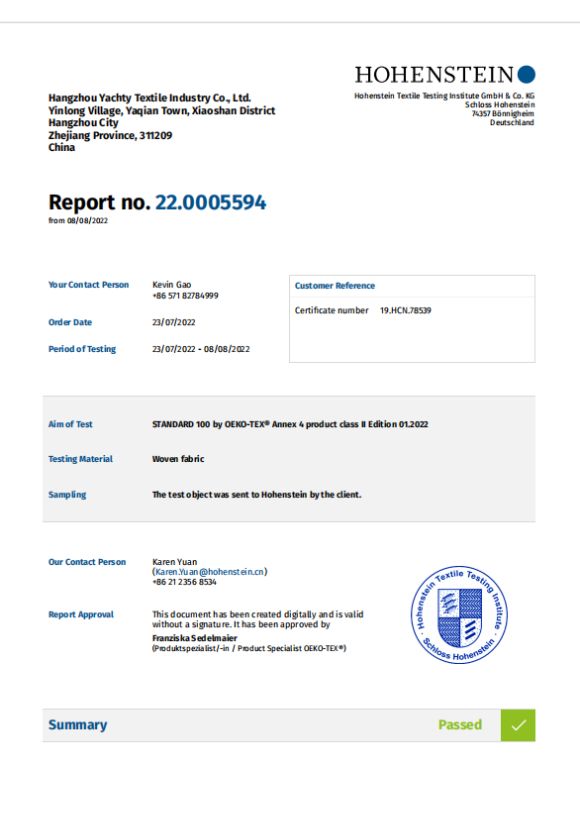

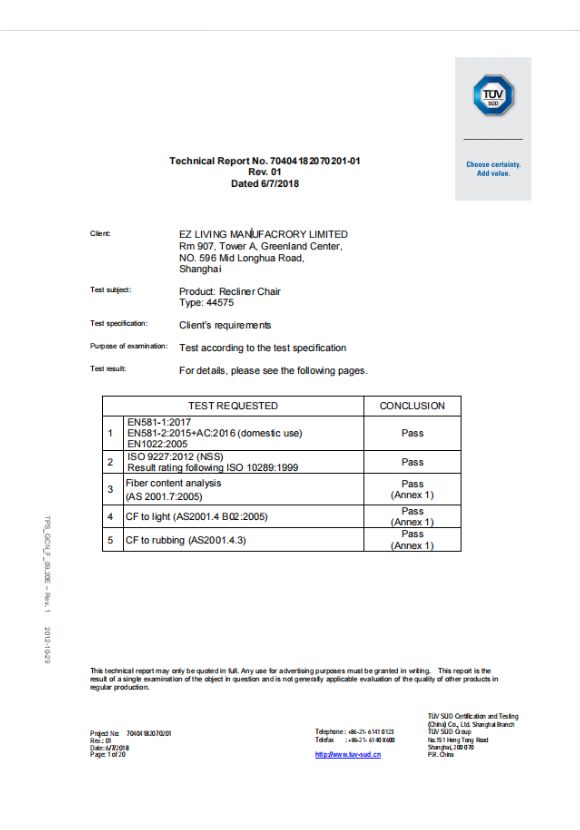

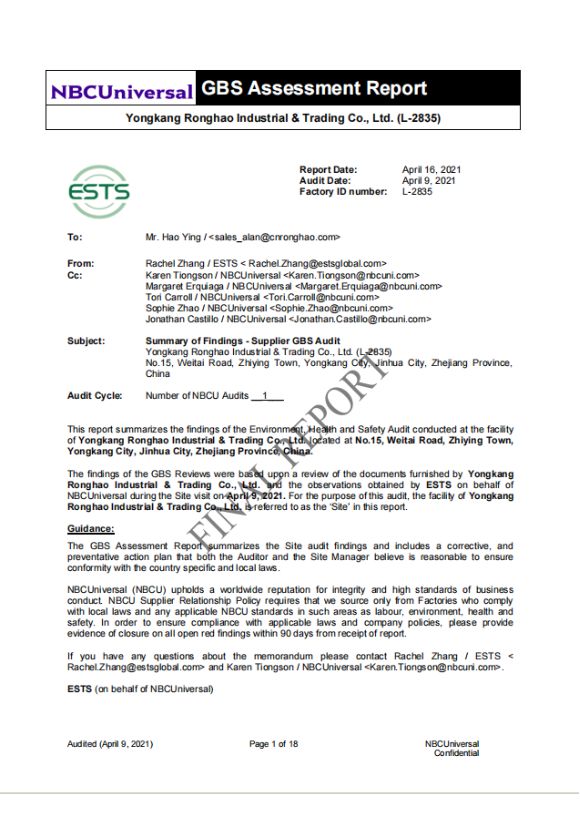

As a leading camping gear manufacturer, we meet and exceed industry standards for safety, quality, and reliability. Our state-of-the-art production facilities are ISO 9001 and 14001 certified, meeting strict international standards.

We engineer camping chairs, tents, stoves and more to the most rigorous quality, safety, and performance benchmarks. Get in touch to order inventoried products or consult our design team on a custom project.

Quality begins with our materials. Our QA team rigorously reviews incoming aluminum, nylon, plastics to detect defects early. This upstream inspection safeguards durability expectations.

We take no shortcuts.

our team

Our team of dedicated gear experts pour passion into every detail. We combine thoughtful craftsmanship with care to keep innovating peak-quality equipment that empowers your brand story